Hydrogen purification from the synthesis gas or any other hydrocarbon stream through pressure swing adsorption is a very common method for providing pure hydrogen stream in oil refineries, olefin plants and chemical industries.

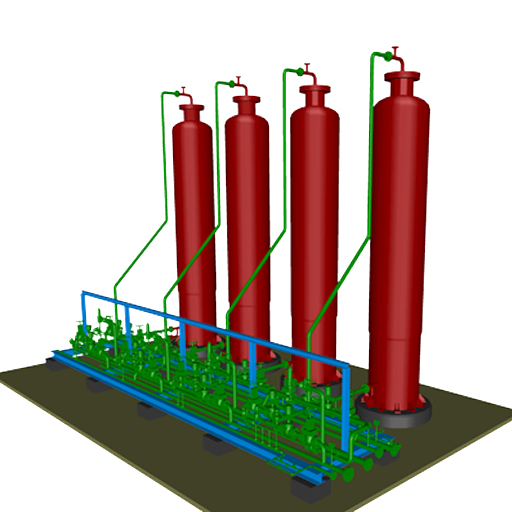

The impurities including carbon monoxide, carbon dioxide, water, hydrocarbons, etc will be adsorbed on different adsorbents loaded in the pressure vessels at high pressure, and in this way purified hydrogen willbe produced The impurities will be desorbed from the adsorbents at lower pressure during certain process sequences.

The whole process in controlled based on the specific time sequences through a precise control system.

Features

- Highly selective adsorbent materials for removing the impurities from the feed gas.

- Precise optimized timing for the swing sequences between high and low pressures

- Non stop reliable and smooth operation due to the automatic control system for switching between different modes and different number of the adsorption columns in case of any failure in the process.

- Wide range of capacities and hydrogen purity ranges

- Inherently safe design to prevent the hazards and minimize the risks

- High efficiency shut off and control valves for minimizing operational failures

- High hydrogen recovery rates 70

- Turndown limits up to 30

Design Options

- Carbon Monoxide analyzer on the purified hydrogen product to monitor the efficiency of the process.

- Optimized design based on 3, 4 and 5 adsorption columns

- Interactive and dynamic graphical control system HMI